A laser alignment tool comes in a user-friendly kit that assists you in correcting and aligning multiple types of misalignments. These lasers are actually making breakthroughs in almost every type of industry. These are utilised on a daily basis and are widely used in different industries, from aerospace and aircraft to mining. There are multiple other industries, such as:

- Pulp and paper industry

- Rubber industry

- Plastic industry

- Shipbuilding

- Electronics industry

- Food industry

- Packaging industry

- Metal industry

- Military industry

- Medical industry

All these industries make use of alignment lasers for maximum accuracy and for precision and to advance the accuracy of their fields. These are used in the manufacturing process to help any kind of machinery to keep in tune and to automatically realign the tools and machinery. It allows the production line to operate more smoothly and efficiently. So in the whole process of services and maintenance, manpower is consumed less, and the production line becomes able to operate constantly rather than the need of shutting down for realignment tasks performed by staff members.

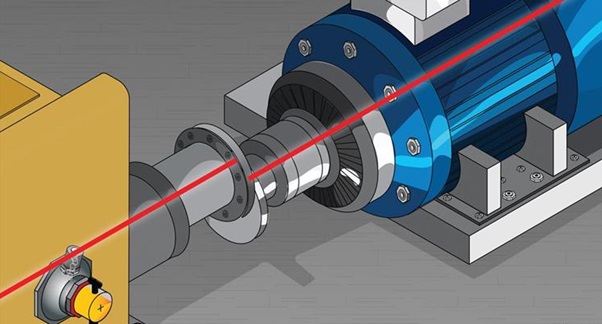

These laser tools are mainly used during the process of manufacturing to help with:

- Installation of machines

- Adjusting indexes

- Presses and shears

- Checking drive systems

- Aligning shafts

- Aligning and correcting gearboxes

- Bearing assemblies

These are not the limited tasks done by alignment lasers as there are many other cost-effective and product enhancing jobs carried out by such laser tools. Since the 1960s, alignment lasers have been using in the construction industry. Mostly, this tool is used in the construction industry to carry out multiple tasks, from building skyscrapers to performing excavation projects. The most frequent use of this tool in the industry of construction is for the purpose of levelling different types of machinery and equipment.

In this process, a beam of laser light is projected. The light is projected to generate lines which permit the floor to be laid evenly and allow walls to be built with optimal precision, as well as it ensures that everything is measured and cut out appropriately according to the requirements and preferences.

Heavy-duty tool operators make use of alignment lasers daily to check on their work and to make sure that the tools and machinery are performing their tasks accurately. Plus, these laser tools make the machinery able to perform the work well with maximum precision that would never be possible without using an alignment laser.

These laser tools are not only limited to the task of correcting the misalignment, but these are also great in providing the data about the specified job that is being planned and about to be executed. Moreover, it is great in providing essential information about the functioning abilities of the tool that will be utilised in the job. They are best utilised to boost the speed of machinery and minimise the level of vibrations and errors that often occur when you don’t make use of alignment tools.

These tools can reduce the errors and make the necessary corrections, and fix the issue that may arise due to the everyday wear and tear happens to the machinery being used on a daily basis. So alignment lasers help out in inspections of tools, structures, as well as specifications that are needed to accomplish a task and to fix a tool being used.

As mentioned earlier, there are various industries that are using this tool to fix alignment issues in their machinery. Likewise, these tools are becoming a critical part of the medical field. In the medical field, it covers the areas of radiation therapy, x-ray technology, as well as much other high technology medical testing. Moreover, these lasers permit pinpoint precision when they need to diagnose and treat the diseases. Plus, the lasers are used to properly align the patient tables to the accurate location and position needed.

So with the help of a laser alignment tool, there are a lot of industries fixing their machinery misalignment errors to keep the machinery running.

Comments