When it comes to dangerous goods packaging, understanding the intricacies can make the difference between safety and disaster. Whether you’re new to the field or looking to refine your knowledge, this guide will walk you through the essentials.

Understanding Dangerous Goods Classes

The first step in managing dangerous goods is understanding their classification. The United Nations (UN) has established nine classes to categorize hazardous materials based on their properties and the risks they pose:

- Class 1: Explosives: Substances that can detonate or deflagrate rapidly. This class includes fireworks, ammunition, and blasting agents. Handling and storing these materials require strict safety protocols to prevent accidental explosions.

- Class 2: Gases: This class encompasses compressed, liquefied, or dissolved gases. Examples include propane, oxygen, and carbon dioxide. Gases can be flammable, toxic, or corrosive, necessitating specialized containment to prevent leaks and pressure build-ups.

- Class 3: Flammable Liquids: These are liquids that catch fire easily. Common examples are gasoline, alcohol, and acetone. Proper storage away from heat sources and the use of flame-resistant containers are crucial to managing these substances safely.

- Class 4: Flammable Solids: This class includes solids that are easily ignitable, self-reactive substances, and materials that emit flammable gases when in contact with water. Examples are matches, magnesium, and calcium carbide. These substances must be stored in dry, cool environments to prevent accidental ignition.

- Class 5: Oxidizing Substances and Organic Peroxides: Materials that can cause or enhance the combustion of other substances. Hydrogen peroxide and ammonium nitrate fall into this category. They require separation from flammable materials and controlled environments to mitigate the risk of fire and explosion.

- Class 6: Toxic and Infectious Substances: Chemicals that are poisonous (toxic) and substances that can cause infections. This includes pesticides and certain medical wastes. Proper labeling and secure packaging are essential to avoid accidental exposure and contamination.

- Class 7: Radioactive Material: Substances that emit radiation, such as uranium and radioactive medical equipment. Handling these materials requires specialized training and equipment to protect against harmful radiation exposure.

- Class 8: Corrosive Substances: Materials that can corrode metals or cause severe damage to living tissue. Examples include sulfuric acid and sodium hydroxide. These substances need to be stored in corrosion-resistant containers and handled with appropriate protective gear.

- Class 9: Miscellaneous Dangerous Goods: Items that pose various hazards not covered in the other classes. This includes environmentally hazardous substances and dry ice. The packaging and handling of these goods depend on their specific hazards and regulatory requirements.

Choosing Appropriate Packaging Materials

Selecting the right packaging materials is crucial to ensuring the safe transport and storage of dangerous goods. The choice of packaging depends on the type of material, its classification, and its physical and chemical properties. Here are some general guidelines:

- Compatibility: Ensure that the packaging material is chemically compatible with the contents. For instance, avoid using metal containers for corrosive substances as they can cause reactions leading to leaks or container failure.

- Durability: The packaging should be robust enough to withstand transportation hazards, including shocks, vibrations, and temperature changes. For example, plastic drums are often used for chemicals because they are durable and resistant to impact.

- Containment: Use leak-proof containers for liquids and airtight containers for gases to prevent any release of hazardous materials. For instance, using proper sealing mechanisms on gas cylinders ensures that there is no gas leakage.

- Absorption Materials: For materials prone to spillage, absorbent materials should be included to mitigate risks in case of a leak. This could involve placing absorbent pads or materials within the packaging to contain any spills.

Common packaging materials include:

- Plastics: Ideal for corrosive substances due to their resistance to chemical reactions. High-density polyethylene (HDPE) is commonly used because of its durability and chemical resistance.

- Metals: Suitable for gases and certain flammable liquids, offering durability and strength. Steel and aluminum containers are often used for pressurized gases and volatile liquids.

- Glass: Often used for highly reactive substances, although it requires careful handling due to its fragility. Glass containers are used in laboratories and for certain pharmaceuticals.

- Fiberboard: Used for solid materials, providing adequate protection and easy handling. Fiberboard boxes are often used for dry chemicals and small equipment parts.

Regulations and Compliance Guidelines

Navigating the legal landscape of dangerous goods packaging can be complex, but compliance is non-negotiable. Regulatory bodies like the UN, International Air Transport Association (IATA), and the U.S. Department of Transportation (DOT) provide guidelines to ensure safety.

UN Regulations

The UN Model Regulations form the basis for most national and international guidelines, categorizing dangerous goods and setting standards for packaging, labeling, and documentation. Compliance with these regulations ensures consistency and safety in the transport of hazardous materials globally.

IATA Guidelines

IATA’s Dangerous Goods Regulations (DGR) are essential for air transport, detailing specific requirements for packaging, labeling, and handling hazardous materials. These guidelines are crucial for ensuring the safety of passengers, crew, and aircraft during the transport of dangerous goods by air.

DOT Regulations

In the U.S., the DOT’s Pipeline and Hazardous Materials Safety Administration (PHMSA) sets forth rules for the safe transport of hazardous materials by road, rail, air, and sea. These regulations are designed to prevent accidents and ensure the safe and secure movement of dangerous goods.

Key compliance steps include:

- Classification: Properly identifying the hazardous material class. This involves determining the physical and chemical properties of the material and assigning the correct classification according to regulatory guidelines.

- Packaging: Using UN-approved packaging that meets the required specifications. This includes selecting packaging materials that are tested and certified for the specific hazardous material.

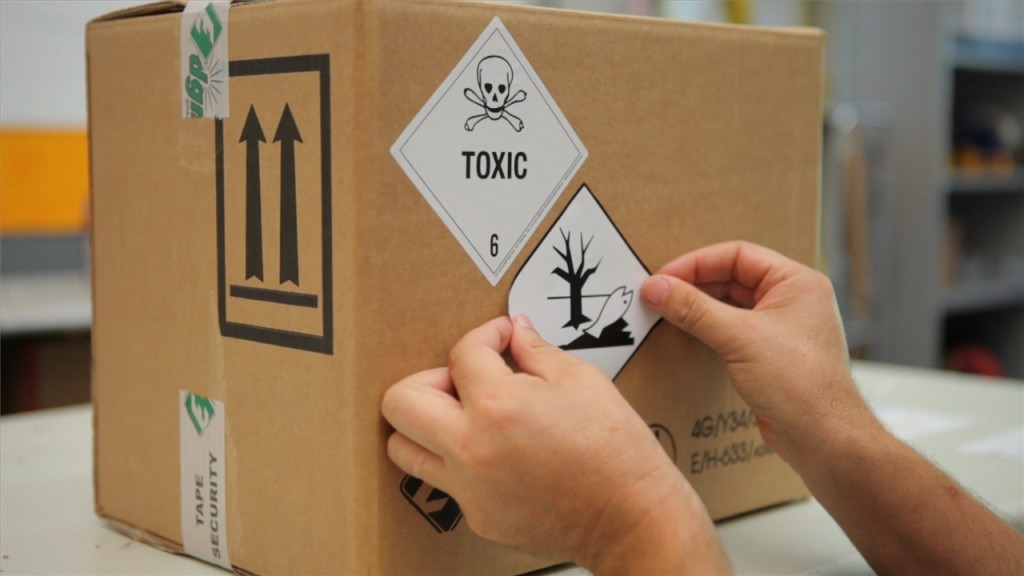

- Marking and Labeling: Accurately marking and labeling packages to indicate their hazardous nature. Labels should be clear, legible, and adhere to the standards set by regulatory bodies.

- Documentation: Providing the necessary documentation, including Safety Data Sheets (SDS) and shipping papers. These documents must accompany the shipment and provide detailed information about the hazardous materials and their handling requirements.

Proper Labeling and Documentation

Accurate labeling and thorough documentation are critical components of dangerous goods packaging. These elements ensure that handlers, transporters, and emergency responders are aware of the risks and know how to manage them safely.

- Labels: Labels must clearly indicate the class of hazardous material. Each label features specific colors, symbols, and text to denote the type of danger. For example, a flame symbol on a red background indicates flammable liquids (Class 3). Labels should be placed in prominent locations on the packaging to ensure visibility.

- Markings: Packages must have the proper markings, including the UN packaging symbol, the UN number for the specific substance, and any other relevant handling instructions. Markings provide essential information about the contents and handling precautions, helping to prevent accidents during transportation and storage.

- Documentation: Essential documents include the Safety Data Sheet (SDS), which provides detailed information about the material, its hazards, and handling instructions. Shipping papers must accompany the shipment, listing the hazardous materials, their classes, and quantities. Documentation ensures that all parties involved in the transportation process have access to critical safety information.

Key Takeaways for Safe Packaging

Understanding the nuances of dangerous goods packaging is essential for ensuring safety and compliance. By grasping the classifications, selecting appropriate packaging materials, adhering to regulations, and maintaining accurate labeling and documentation, you can mitigate risks and facilitate the safe transport of hazardous materials. Remember, thorough preparation and attention to detail are your best tools in managing dangerous goods effectively. Proper handling and adherence to regulations not only ensure safety but also promote efficiency and reliability in the transport and storage of hazardous materials.

Comments