Did you know that there are over 565,000 manufacturing businesses in the USA?

While you might think that the entire manufacturing industry has been shipped to the far east, this is not true. Manufacturing is alive and well in America today.

One reason for the survival of manufacturing in the USA is the use of the latest technology. For example, did you know the industrial applications of laser technology in the manufacturing sector?

Why not take a few minutes to read our article and find out how they are being used to save time and money.

- Laser Marking

Companies are increasingly using lasers to imprint makes and tracking information on parts. This not only allows them to easily identify them. The company can also track them at later stages. This is especially useful when there is a need to recall products.

If you are interested in using lasers to identify and mark products, why not click here to find out more.

- Welding

Manufacturers that are looking to create complex welds between materials that do not usually bond are making more and more use of laser welding.

In many cases, laser welding is proving to be more effective than gluing or traditional welding techniques. It can produce an extremely precision weld of as small as 0.004 inches. These welds are as strong and long-lasting as those produced by traditional welding techniques.

- Creating Texture on Surfaces

Many surfaces require texture or a key in order for other surfaces to adhere to them. Some surfaces, such as bones, are difficult to reach, and so traditionally, this texturizing has proven difficult.

However, lasers can be used to create this texture. Technicians can do this in very difficult locations that require precision handling.

- Drilling

During the manufacturing stages, it may be necessary to drill holes of incredibly small diameters. With traditional drills and bits, this is often impossible. However, laser drilling can drill astonishingly small holes.

Lasers can drill micron-sized holes in even very hard materials such as ceramics and metals. However, because of the nature of laser technology, it can do this while creating very little heat.

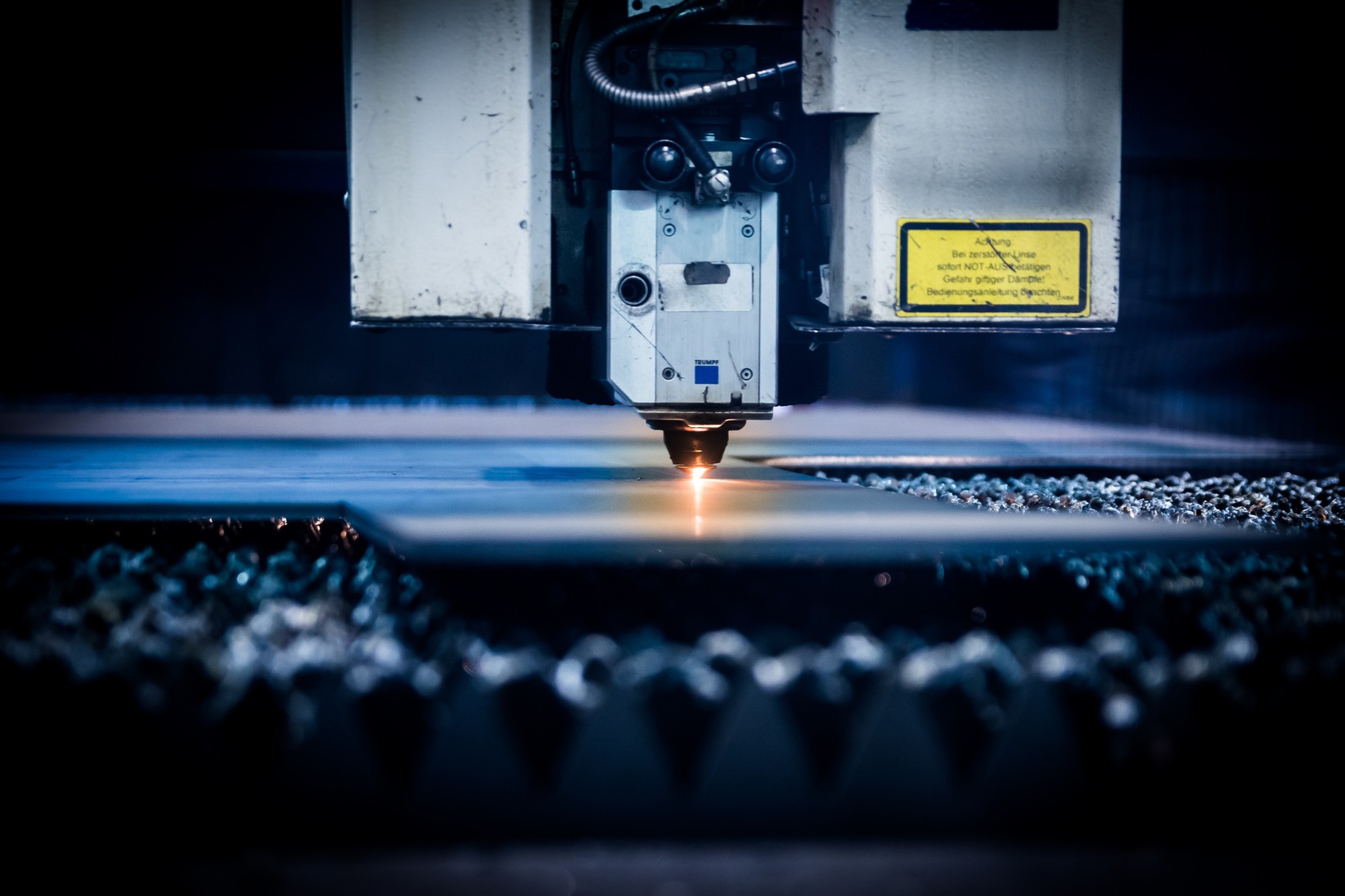

- Cutting

Lasers not only cut very quickly, but they also create incredibly clean cuts. Traditional cutting machines rely on a spinning blade or a back and forth sawing motion. The stresses that this creates can often leave marks on the cut edges.

However, since laser technology literally cuts through using precision beams of light, it will not cause the same damage.

How to Leverage the Industrial Applications of Lasers and Much More

If you are considering entering the manufacturing market, you likely want to learn about the industrial applications of laser technology. It is an incredibly accurate, clean, and often cheap tool that can help you to cut time off the manufacturing process.

People who are in business in 2020 need more sound advice and trustworthy information than ever before. Why not check out what we are publishing on our blog page. Find out how we can help you today.

Comments